The term ’processability’ can be defined as the ease with which polymers, whether neat or compounded, can be handled on the manufacturing lines (i.e., in production operations and equipment), where the end-user manufacturer is primarily concerned with the processing quality of the polymer-based product, and is sensitive to factors that may affect the materials’ behavior and variability during the manufacturing steps. Understandably, the selection of (polymeric) materials for a specific application has to take into account not only the material suitability, but also its processability. A material having all the required properties to achieve satisfactory product performance, but not easily and economically processible, is often discarded.

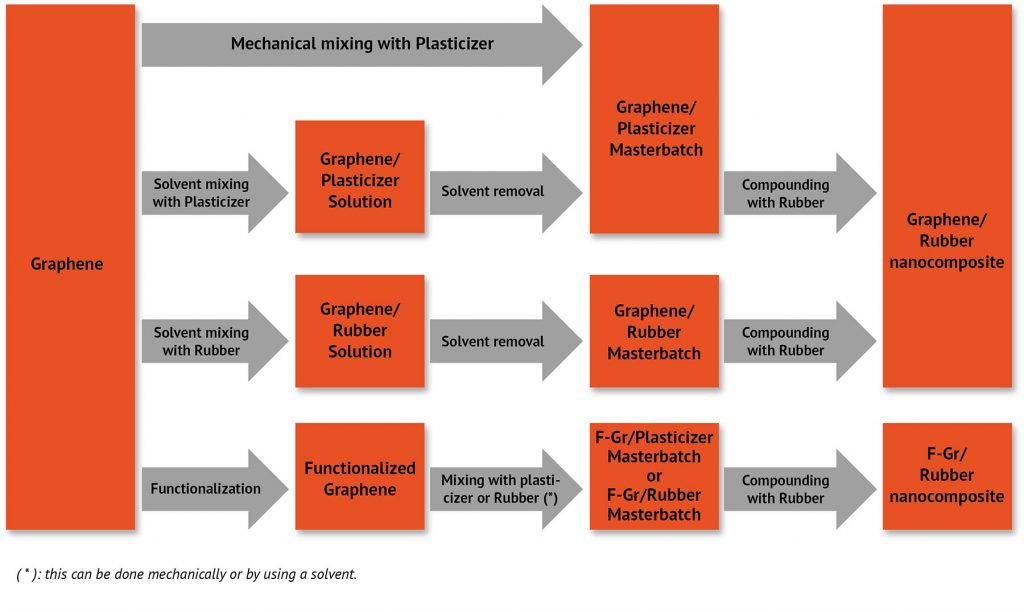

Similarly, graphene processability is often cited as one key technical obstacle to overcome in in order to enable widespread uptake of graphene by industry. More specifically, it is the requirement to achieve cost-effective, stable and homogeneous dispersions of graphene without agglomeration, while ensuring strong interaction with the polymer matrix (Source: Fullerex Ltd.). In this regard, CealTech has the ability to bring all these elements together effectively, as illustrated in the schematic below, which shows the example of a project where we are investigating the use of graphene in rubber material, where rubber can refer to natural or polybutadiene rubber.

The schematic above shows some of the methods we are evaluating in this project, including direct mixing, either mechanically or by using a solvent; or by functionalization (for more information, refer to our article about ‘Graphene Functionalization’). Needless to say that it is paramount with a stable and homogeneous dispersion throughout the project development, to achieve optimum properties and performance.

For more details, contact sales@cealtechdev.wpengine.com You can also keep on checking our website as we will be publishing routinely further update on the progress from the project mentioned in this article.